We specialize in 3, 4, and 5-axis milling, high precision turning and micro Swiss machining, offering high-quality parts tailored to your specifications.

Our comprehensive approach covers prototype verification, low-volume pilot production, and high-volume manufacturing, ensuring smooth handling from start to finish.

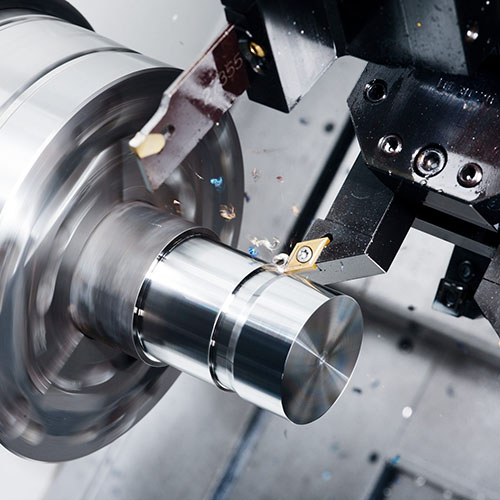

In turning, a lathe machine rotates a workpiece while a cutting tool removes material to create cylindrical shapes such as shafts, rods, and discs.

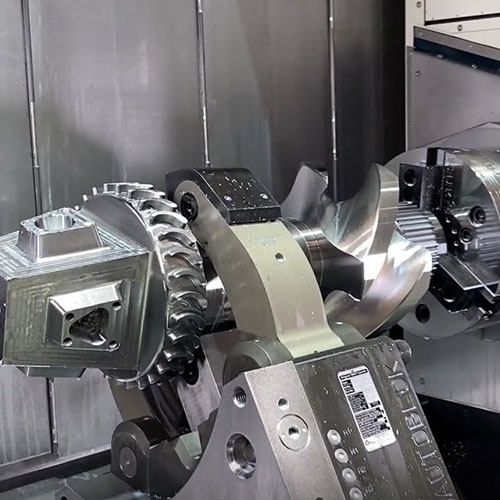

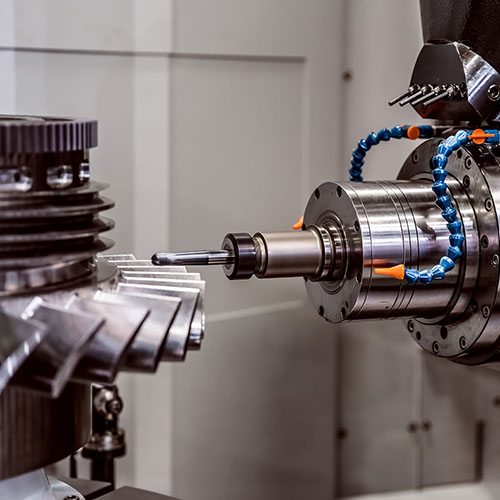

Milling involves rotating cutting tools with multiple teeth to remove material from a workpiece's surface, creating complex shapes, slots, and holes.

Drilling uses rotating drill bits to create cylindrical holes in a workpiece, often for fasteners or to accommodate other components.

Grinding uses the friction on the grinding wheel to remove excess scraps or burrs from the material and to achieve a precise surface finish on the workpiece.

Sawing includes the use of saw blades to cut workpieces, often used in products such as sheet metal or wood plastics through straight or curved cutting to complete the relevant product requirements.

High-precision machining of complex geometries is possible through five axes of motion (X, Y, Z and two rotational axes).

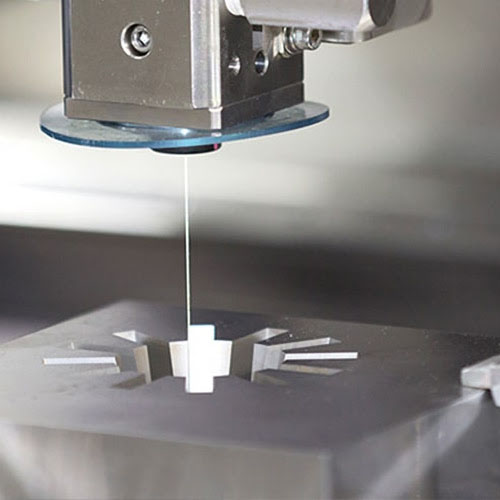

Wire cutting utilizes spark erosion for processing and is a precision manufacturing technology that is particularly suitable for parts with complex shapes and high precision requirements.

It is processed by rotating a tap into a pre-drilled hole and tapping to produce an internal thread on the workpiece or in a custom form.

CAPACITY(X-Y-Z): 250/400 mm

Tolerance: ±0.01mm

2 Machines

CAPACITY(X-Z): 275/1000 mm

Tolerance: ±0.01mm

2 Machines

CAPACITY(X-Z): 142/165 mm

Tolerance: ±0.01mm

1 Machine

CAPACITY(X-Z): 175/550 mm

Tolerance: ±0.01mm

1 Machine

CAPACITY(X-Y-Z): 1350/750/750 mm

Tolerance: ±0.003mm

1 Machine

CAPACITY(X-Y-Z): 500x400x300 mm

Tolerance: ±0.001mm

1 Machine

CAPACITY(X-Y-Z): 800/500/500 mm

Tolerance: ±0.005mm

8Machines

CAPACITY(X-Y-Z): 800/500/530 mm

Tolerance: ±0.003mm

3 Machines

| Size | Metric units | Imperial units |

| Max. part size for soft metals [1] & plastics | 2000 x 1500 x 200 mm 1500 x 800 x 500 mm | 78.7 x 59.0 x 7.8 in 59.0 x 31.4 x 27.5 in |

| Max. part for hard metals [2] | 1200 x 800 x 500 mm | 47.2 x 31.4 x 19.6 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

| Size | Metric units | Imperial units |

| Max. part size for all materials | 2000 x 1500 x 200 mm | 78.7 x 59.0 x 7.8 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

| Limits for nominal size | Plastics (2768- m) | Metals (2768- f) |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 120mm to 401mm | ±0.8mm | ±0.3mm |

| Over 120mm to 402mm | ±1.2mm | ±0.5mm |

| Over 120mm to 403mm | ±2mm |

| Part size limitations | Metric units | Imperial units |

| Maximum part diameter | 431 mm | 17 in |

| Maximum part length | 990 mm | 39 in |

| Maximum swing over the carriage | 350 mm | 13.7 in |

| Maximum spindle through-hole | 40 mm | 1.5 in |

| Limits for nominal size | Plastics (2768- m) | Metals (2768- f) |

|---|---|---|

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.3mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.5mm |

| Over 2000mm to 4000mm | ±2mm |

| Size | Metric units | Imperial units |

| Max. part size for soft metals [1] & plastics | 2000 x 1500 x 200 mm 1500 x 800 x 500 mm | 78.7 x 59.0 x 7.8 in 59.0 x 31.4 x 27.5 in |

| Max. part for hard metals [2] | 1200 x 800 x 500 mm | 47.2 x 31.4 x 19.6 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

| Size | Metric units | Imperial units |

| Max. part size for all materials | 2000 x 1500 x 200 mm | 78.7 x 59.0 x 7.8 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

| Limits for nominal size | Plastics (2768- m) | Metals (2768- f) |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 120mm to 401mm | ±0.8mm | ±0.3mm |

| Over 120mm to 402mm | ±1.2mm | ±0.5mm |

| Over 120mm to 403mm | ±2mm |

| Part size limitations | Metric units | Imperial units |

| Maximum part diameter | 431 mm | 17 in |

| Maximum part length | 990 mm | 39 in |

| Maximum swing over the carriage | 350 mm | 13.7 in |

| Maximum spindle through-hole | 40 mm | 1.5 in |

| Limits for nominal size | Plastics (2768- m) | Metals (2768- f) |

|---|---|---|

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.3mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.5mm |

| Over 2000mm to 4000mm | ±2mm |